When I started planing my build I intended to use the external Rotax alternator, since the internal PMG only produces up to 18 amps. (Hello, electrically heated seats!!) However, as I got to know the SeaRey I realized that it had a weight problem, and decided to reduce the “goodies” to try to keep the electrical load within the 18 amp limits of the PMG. Good practice says you should limit your electrical load to 80% of the generator output, and the 914 manual recommends that if your aircraft requires loads above 12-15 amps you should use the external alternator. (Goodbye, electrically heated seats...)

While cutting the panel Jim showed me the external alternator he was installing on another aircraft. It was smaller than I thought, and only 8#. Of course, in addition to those 8# there is the wiring, etc it adds to the airplane.

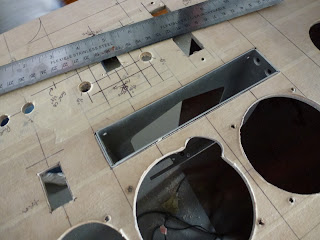

As we continued cutting the panel we talked more about the pros and cons of adding the external alternator vs the weight penalty. The generator on the Rotax 914 is a “permanent magnet generator”, which means the magnets are fixed to the outside of the engine, the engine flywheel acts as the armature, and the rotation of the engine directly produces the electrical current for the plane.

Since both fuel pumps are electrically powered, as the manual states “In all cases the electrical system design should assure that no single failure mode (IE: alternator, battery, voltage regulator) causes both fuel pumps to stop. Careful design consideration must be given towards this issue!”

While it would take a lot to cause a PMG to fail, Jim led me down the primrose path by asking me what I intended to do when I started flying Osp. “A lot of landings!!” I replied. We then discussed the power output of a generator, that it only developed power when at a higher rpm, and the lower the rpm, the lower the electrical output. As we all know, when in the pattern full power is used for takeoff but once at altitude power is reduced for level flight on the downwind, and further reduced for descent and landing, resulting in lower generator electrical output, and fewer amps for the system.

So while in the pattern, what's going on? Radio calls are being made and received, nav/strobe/landing lights are on, power is being used by the Skyview, but most importantly-the electric landing gear is being cycled, putting a high load on the electrical system.

The SeaRey is the only retractable gear aircraft I have ever flown that does not have a backup gear extension system, and it's kept me up many times at night. It's an elegant, yet simple system using dual electric motors for main gear extension/retraction and a garage door spring for tailwheel retraction (slaved to the left gear actuator for extension). But since it uses separate gear actuators, a bad day could see you with the gear stuck up or down, and a real bad day (like a failed connection ) could leave you with one gear up and the other one down, and few good alternatives.

More realistically, when doing pattern work the combination of low electrical power output and high electrical demand might end up inadvertently draining the battery, leaving you without enough power to extend the gear. While you could go fly around and charge up the battery, the SR has a narrow weather window, and if the winds or weather were kicking up, that might not be a good option.

End result, I'm reversing my decision not to go with the external 40 amp (Hello, electrically heated seats!!) alternator, and will be adding it to Osp.

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

+(Medium).JPG)

+(Medium).JPG)

+(Medium).JPG)

+(Medium).JPG)

+(Medium).JPG)

+(Medium).JPG)

+(Medium).JPG)

+(Medium).JPG)

+(Medium).JPG)

+(Medium).JPG)

+(Medium).JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)