Note to self: when taking photos of wire locations/labels, make sure camera is in focus before moving on.

Like this.

Wires all removed and organized, there's my trophy fish.

With the layout roughed out, it was time to replace the cardboard with the real things. Even then, I still (almost) screwed up, only blind luck saved me. More on that later.

One thing we tried was having the power buss backwards so the wires could be ran along the back of the shelf, but with the nosedeck on I found I could not reach or locate the terminal connections, so that idea got squelched. Note how all the wires got ziptied or taped together according to their destination (buss 1, 2, ground, etc), or function.

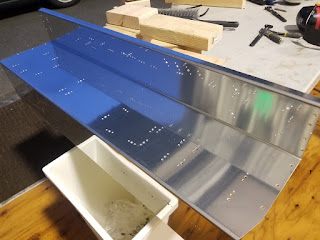

And with final locations determined, it was time to start drilling.

*gulp*

THAT was a late night, but I tend to be nocturnal, and once I get in a groove I like to keep going. Note also the new

ARTEX 345 ELT. (Me: I was thinking about this ELT. Syd: You're not getting that one, you're getting this one. Me: Ok.)

Nutplates vs nuts were a big debate. TJ hates nutplates because of dissimilar metal corrosion between the steel nutplates and aluminum structure, but Syd & I held firm that they were almost mandatory for field repairs. We came to a compromise: nutplates, but before they were mounted the shelf would be epoxied so there would be no dissimilar metal contact. Fair enough.

I wasn't going to buy a jig just for drilling the nutplates, now I wonder how I did without. SO much easier!!

Shiny!!

With the parts mounted, it was time to run wires. Here's where I almost messed up. You can see the transponder in the upper left of the tray, I was going to put the capacitor to it's left but forgot to drill the holes for the clamp. Had I done that, there would have been a conflict between the capacitor and the cable coming out the transponder. Dumb luck that I forgot about the capacitor, but I'll take that. Instead, it's going to go in the center of the panel on the lower shelf between the backup battery and the Fastack hub.

Just for fun, here's how da big boyz do wiring. Wonder how much they charge for those zipties?

...