After Jim received the panel he covered it with masking tape to protect it, and transferred the equipment locations over. Quite a few hours of work there to make sure things lined up, and he made small shifts to some items to make it more aesthetically pleasing.

What looks like a small object from the front may be deceptively large behind the scenes. From top to bottom: a switch, circuit breaker, and start switch all have a considerable amount of hardware behind their small display face.

The vibration triggered Hobbs meter

eliminates the need to run a wire to the oil pressure in the engine,

so the cover plate is actually bigger than the actual unit.

In the old days engineers would actually make cockpit mockups-and in some cases even entire airplanes-out of wood to make sure systems fit, and instruments were readable and reachable by the pilots. Nowadays this is done all on a computer, and the Boeing 777 I fly was the first to be completely done on computer. In this case, Jim suggested we have the switches 1” apart, while I felt a minimal spacing of 3/4” was fine. A piece of cardboard substituted for the panel, and the 7/8” spacing turned out to be juuuuust right.

Those boxes are mostly full of air,

with little tiny rectangles of electronics inside. Yes, I had to open

each one up and look, even though I was like a dog looking at a TV.

“Yup, that's a box.”

Oooooooo.... so fun to have my MFD in

real life. Now put it down, Steve,

Wall-E? Nope, this is how Dynon updates their Skyview software. You download to a USB drive and plug it in. Cool.

This is really cool. I’m not going to

do a lot of night flying, but I want the capability to stay up and

watch the sunset, or if I want to get an early start to a trip and

takeoff before sunrise, I want full night ops capability. This is a

UMA light bezel, and instead of standard GA lighting via a post with a

small light bulb inside, or lights behind a panel, this ring fits

over the instrument and gives a soft, even illumination. Also note the airspeed indicator. Yeah,

she's not going to be a speed demon, a real Osprey

could probably outdive her.

A couple major changes were made-the

Cessna split master switch was meant to be put into a thin sheet

metal panel, and not into a 3/16” fiberglass/veneer laminate, so we

decided to use separate toggle switches for the master and generator.

After a long discussion and thinking it over, I also decided to go

with the additional weight of the Rotax supplementary alternator.

More on that in another post.

An interesting contrast going on outside Jim's hangar, as Valkaria Airport adds a row of hangars. Kinda fun to watch the little birds dance around the shovel as it digs, but...

The bad thing is all the dust and dirt it puts into the air that blows it's way into the hangar. Can's close the door or we'll steam.

One great suggestion he had was to talk

me out of the green and blue mnemonic strips, and clean up the center

panel area. Removing them gave an elegant look to the panel, and took

away some cheesiness. I hated to ask it, but some things

required Jim to redo his drawing.

It begins. Jim gets the feel for

drilling the panel using the area inside the Dynon that will be

scrap. Later he shows me a photo album, including an airplane he

built years ago with a panel from a solid piece of teak wood. A quiet, soft spoken man, I'm

learning a lot being around him.

I know that look- it means "I'm concentrating, leave me alone." I did.

After the drilling comes the cutting.

By this time it was mid-afternoon, and after getting back from doing a min rest Hong Kong flight I was finally feeling human again and ready to take my turn. I started my shift with the flap controller because it had a large cover plate that would (hopefully) cover up any screwups, but I didn't make any. It still makes me shake my head when I think that I'm being paid to fly big airplanes to far off places. I’m grateful, and worry that one day I’m going to wake up and be back waiting tables.

Gut check. My idea to cut the big

holes for the analog instruments by starting with small ones inside

and work our way out with a Dremel sanding drum, but Jim had some

hole saws that he used in other panels. As always, a test cut was made

in the Dynon area.

Excellent... it worked perfectly. Can he do

it 3 times in a row?

I should know better than to think he

freehands this stuff, a well used jig starts things off.

There's a reason sometimes you should

hire professionals and then get out of the way. 3 perfect cuts later

he uses the Dremel to grind out the opening for the altimeter setting

knob.

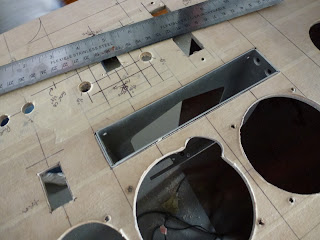

Now the fun stuff: radio installation.

If you look closely under the ruler you'll see the opening for the

gear switch, and LED position lights, you can also see where I made a

small adjustment and moved the Gear Alert light 1/8” from where I

had previously decided. Small adjustment, and I felt silly doing it,

but later when everything was done I was very happy I had changed it.

Took a little creative maneuvering to install the radio while I was making the final cuts.

While I was cutting, Jim made the radio

mount brackets.

The final cut. I was terrified I was

going to cut on the wrong side of the line, or something else dumb.

Perfect I started breathing again.

Final fittings.

Before

After

I had to sit a while and take it in. In

all modesty, it's a beautiful panel, it was worth all the work and I can't

wait to see it stained and varnished. Note that the bottom of the wing panels

taper inward. When Gordon and I were fitting the panel we were

getting worried because we thought those lines should be perfectly

vertical, and I was racking my brain trying to figure out what I had

done wrong. Turns out the hull DOES taper from top to bottom, and the

panel should be like this. I did make an error in the panel, it's become a private joke between us and I

don't think Jim is going to let me live it down, but I don't think

even the sharpest observer will find it.

Got some reading to do before I can

punch buttons, and I know I’ll have me share of finger fires until

I get used to it. In the glass cockpit EMB-145 airliner I was a Check

Airman in, I used to tell students that it took 100 hours to start to

feel comfortable, and 3-500 hours to know what they were doing. Obviously, I’m going to have to learn this faster.

Pack it,

And ship it. It was waiting for me when I got home the next day, but it had been opened and sloppily retaped. No damage, no note, nuthin' to explain why. Next will be final trimming/fitting, labels, and trying to

figure out a way to cut and hinge a glove box in the space on the

right side of the panel.

Reality

PAR100EX radio

ACI gear alert system

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)